Steel Dock Boards: Elevating Efficiency in Warehouse Operations

In the relentless pace of warehouse operations, where every moment matters, the quest for efficiency becomes paramount. Finding practical solutions to enhance productivity is essential for professionals overseeing industrial facilities. Steel dock boards offer a reliable and indispensable tool designed to simplify the loading and unloading process, ensuring seamless operations in your warehouse.

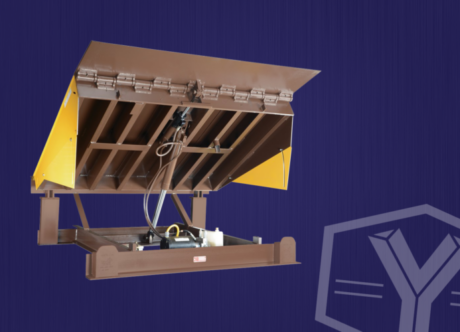

What Are Steel Dock Boards?

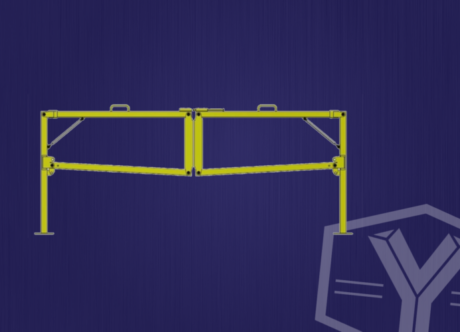

At their core, steel dock boards are purpose-built fixtures crafted to facilitate the movement of goods between trucks and loading docks. Specifically designed for use with two-wheel hand trucks, these boards provide a convenient, safe, and efficient means to access loading docks from trucks. Their lightweight design ensures easy portability by a single person, offering a seamless solution for foot or hand truck traffic.

Benefits and Features

Enhanced Safety and Efficiency:

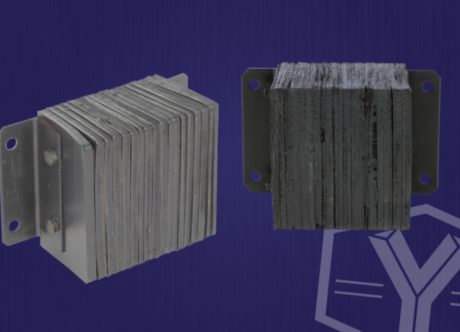

Safety is paramount in any industrial setting. Steel dock boards address this concern with a thoughtful design that prioritizes safety and efficiency. The beveled entrance and exit edges contribute to a smooth transition, reducing the risk of accidents during the loading and unloading process. The treadplate surface ensures skid-resistant safe traction and provides a secure platform for operations.

Zinc-plated locking legs and lifting handles add an extra layer of safety, securing the plate firmly in place during operations. These features not only adhere to OSHA compliance standards but also contribute to an overall safer working environment, minimizing the likelihood of accidents and injuries.

Versatility and Adaptability:

Warehouses are dynamic environments with diverse operational needs. Steel dock boards are designed and manufactured from high-quality steel, ensuring durability and longevity. The availability of various widths allows for customization to suit specific dock and forklift applications. This adaptability ensures that this product seamlessly integrates into your facility’s unique requirements.

Additionally, the option to order custom-made dock boards provides a level of versatility that caters to the specific demands of your operations. This bespoke approach ensures the steel dock boards align perfectly with your facility’s layout and operational nuances.

Cost-Effective Solutions:

Efficiency in warehouse management shouldn’t come at the expense of budget constraints. Steel dock boards offer a cost-effective solution without compromising on quality. Available in both new and used options, these boards are built to handle the demands of daily operations, providing a reliable and budget-friendly solution for warehouse managers.

With a substantial capacity, these boards can confidently accommodate the varied loads encountered in warehouse settings. The combination of durability, customization options, and cost-effectiveness makes this dock equipment prudent for facilities aiming to enhance efficiency without breaking the bank.

Industry Use Cases of Steel Dock Boards

Steel dock boards are pivotal in optimizing dock operations across various industries. These temporary fixtures are essential when the dock lacks a fixed loading dock plate. Acting as an extension of the dock itself, the dock board is bolted to the dock plate, providing a solid foundation for dock levelers to operate effectively.

Warehouses and industrial facilities rely on steel dock boards to seamlessly bridge the gap between trucks and docks. This functionality becomes particularly critical when dealing with trucks that lack a dock door. Steel dock boards enable forklifts to access loading areas efficiently, ensuring a continuous flow of goods without disruptions.

Customization Options for Steel Dock Boards

One of the standout features of steel dock boards is their adaptability to diverse operational needs. The customization options available cater to the unique requirements of different facilities. These can be tailored to meet your specifications, whether you need a specific width or length to fit your dock and forklift applications.

Custom-made dock boards offer precision that seamlessly integrates into your facility’s layout. This bespoke approach enhances the overall efficiency of loading and unloading operations, as the boards are optimized to address the specific challenges of your warehouse.

Conclusion: Investing in Practical Efficiency

Steel dock boards emerge as indispensable tools in the ever-evolving landscape of industrial facilities, where efficiency is not just a goal but a necessity. Their sturdy design and versatile customization options position them as reliable partners in optimizing loading and unloading operations. Warehouse managers overseeing daily operations will find a practical solution that aligns with their priorities.

Investing in steel dock boards goes beyond acquiring equipment; it’s a strategic move toward enhancing warehouse operations’ overall efficiency and safety. The thoughtful design, cost-effectiveness, and adaptability make steel dock boards a valuable asset for middle-aged professionals navigating the complexities of warehouse management. As you seek practical solutions to elevate your facility’s efficiency, consider the transformative impact that these boards can bring to your daily operations.

We have new and used dock boards in stock.

Size: 60″w x 60″ L

Price: $950.00

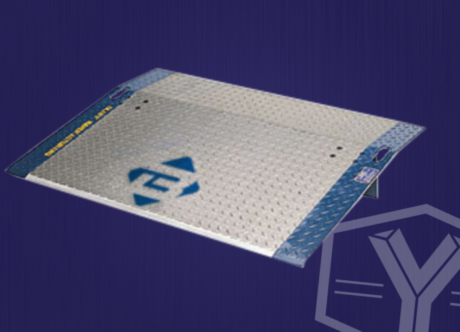

New: Model # AC6060

Height differential is 7″. Steel curbs are bolted to the aluminum diamond pattern plate for increased strength, and to help prevent runoff. Locking legs provide secure positioning. Lip bend is 11°. Standard lip length for conventional trailers is 11″, option of 14″ for refrigerated applications. Widths from 60″ to 72″, and lengths from 36″ to 96″. Capacity: 10,000 lbs.

Size: 60″w x 48″ L

Price: $775.00

New: Model # AC6048

Steel curbs are bolted to the aluminum diamond pattern plate for increased strength, and to help prevent runoff. Locking legs provide secure positioning. Lip bend is 11°. Standard lip length for conventional trailers is 11″, option of 14″ for refrigerated applications. Widths from 60″ to 72″, and lengths from 36″ to 96″. Capacity: 10,000 lbs. Weight: 165.

Please contact for more information about available dock boards.