Pallet Scales: The Ideal Solution for Heavy-Duty Weighing Needs

Pallet scales are essential tools for businesses that require accurate and reliable weight measurements of large or heavy loads, especially those that come in palletized formats. These specialized scales are designed to handle the weight of entire pallets, skids, or containers, making them ideal for warehouse environments, logistics centers, manufacturing facilities, and more. With their robust design and precision, scales provide an efficient way to manage inventory, optimize shipping processes, and ensure compliance with weight regulations.

What Are Pallet Scales?

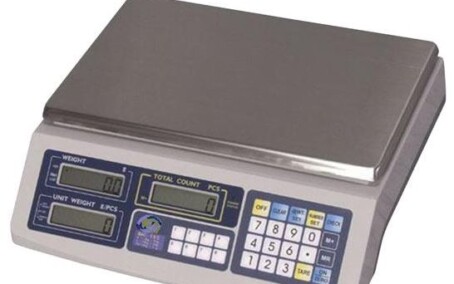

Pallet scales are heavy-duty weighing devices designed to weigh large, bulky items that are typically placed on pallets or skids. These scales are built to handle high-capacity loads, often weighing up to several tons, and are usually constructed with a durable metal frame to ensure longevity and accuracy under demanding conditions. Unlike standard scales, pallet scales are equipped with a larger platform area to accommodate pallets or skids, making them perfect for weighing items in warehouses or shipping docks where palletized goods are common.

These scales can be used to weigh a variety of goods, including boxes, containers, and raw materials, and are equipped with precision sensors to ensure highly accurate readings. They also often come with digital displays that show the weight in various units such as pounds, kilograms, or ounces, depending on the user's preference.

How Do Skid Scales Work?

Skid scales, often used interchangeably with pallet scales, function similarly by weighing items placed on them. The main difference is that skid scales are typically more compact and often used for lighter loads or smaller-sized skids. These scales offer the same basic functionality as pallet scales, allowing users to easily measure the weight of goods on a skid or platform. The process is simple: place the skid or pallet on the scale, and the scale will calculate the weight based on its sensors and display the result.

Like their larger counterparts, skid scales offer a wide range of capacities and features, from simple analog models to advanced digital versions that integrate with inventory management systems. The versatility of skid scales makes them suitable for a wide variety of applications, from small businesses to large warehouses.

Benefits of Pallet Scales

- Accuracy: Pallet scales provide highly accurate weight readings, ensuring that businesses can confidently rely on their data for inventory tracking, shipping, and regulatory compliance.

- Increased Efficiency: With a large, flat platform to accommodate pallets or skids, pallet scales simplify the weighing process and improve workflow efficiency. They allow employees to quickly weigh multiple items at once without the need to manually move them onto different scales.

- Durability: Designed to withstand heavy usage, scales are built from high-quality materials such as stainless steel or reinforced steel. This durability ensures that they can handle tough warehouse conditions, including rough handling, impact, and extreme weight loads.

- Space-Saving Design: Many modern scales come in low-profile designs, making them easy to install in areas with limited space. Their compact size and robust construction make them a smart addition to any facility, especially those where floor space is a premium.

- Cost-Effective: By investing in pallet scales, businesses can save on labor costs, reduce errors associated with manual weighing, and improve the accuracy of their inventory management systems. This can lead to lower overhead and better resource allocation.

Choosing the Right Pallet Scales

When selecting skid scales for your business, consider factors such as weight capacity, platform size, and the type of display (analog vs. digital). Some scales are designed with built-in wheels for portability, while others are fixed in place for more permanent installation. For industries that require frequent, heavy-duty weighing, look for models with enhanced durability and accuracy features, such as high-resolution sensors and adjustable calibration.

Conclusion

Pallet scales are an invaluable tool for any business that deals with large or heavy palletized goods. Whether you're weighing shipments, managing inventory, or ensuring compliance with weight regulations, skid scales offer a reliable and efficient solution. With their precision, durability, and ease of use, these scales are designed to improve operations, save time, and reduce errors in high-volume environments. Invest in pallet scales today to enhance the efficiency and accuracy of your business operations.