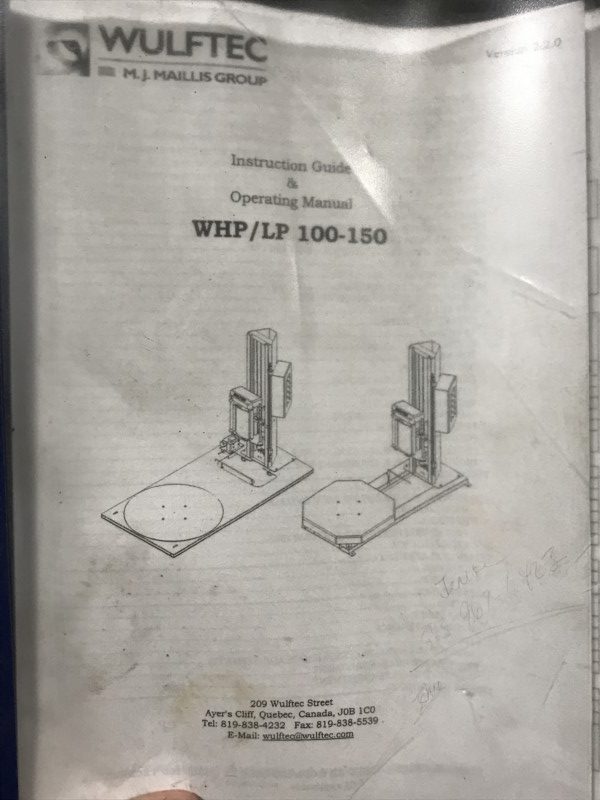

Introducing the Pallet Wrapper – Pallet Stretch Wrapping Machines: Efficient and Secure Packaging Solutions

Crafted for Efficiency: Robust Construction and User-Friendly Controls

Our machines, called Pallet Wrappers or Pallet Stretch Wrapping Machines, make it easier to package goods on pallets while keeping them secure during transportation. We prioritize the safety and stability of your merchandise during transit. Businesses can improve their packaging processes with these machines. They are strong, have simple controls, and can wrap in many ways.

Built to Last: Durable Materials for Long-Term Reliability

Our pallet wrappers feature a robust construction that ensures durability even in demanding environments. These machines are built for longer use and can handle daily usage. This guarantees that your packaging requirements will be met with dependable equipment.

Versatile Stretch Films: Optimal Performance for Unique Needs

One standout feature of our pallet wrapping machine is its compatibility with various stretch films. Choose the most suitable film for your specific requirements, whether standard or specialized. Our machines adapt to your unique needs, ensuring optimal performance with flexibility in packaging materials.

User-Friendly Interface: Easy Operation and Time Savings

The user-friendly controls make operating our pallet-wrapping machine a breeze. Operating without specialized training is easy, saving your team valuable time and resources.

Customizable Wrapping Settings: Tailored to Your Requirements

Efficient pallet wrapping requires customization, and our machines provide precisely that. With adjustable wrapping settings, control parameters such as wrap tension, speed, and the number of revolutions. This adaptability ensures that each pallet is perfectly wrapped and tailored to your requirements.

Safety First: Latest Safety Measures for Operator Protection

Our company values the safety of our operators above everything else. Therefore, we have equipped our pallet wrappers with the latest safety features. In addition to emergency stop buttons, our machines are equipped with advanced safety sensors that detect potential hazards and promptly halt operations. We ensure to have a safe workplace for every operator to lower the occurrence of accidents and injuries. These measures help create a secure working environment.

Versatile Handling: Adaptability for Various Pallet Sizes and Shapes

Versatility is another hallmark of our pallet wrappers. They can handle small or large pallet sizes, irregular shapes, or varying configurations, seamlessly integrating into your existing packaging processes and accommodating diverse needs.

Automation for Increased Productivity: Automatic Film Cutting and Clamp Features

Automation is a game-changer in packaging, and our pallet wrappers deliver on that front. Automatic film cutting and clamp features eliminate the need for manual intervention, saving time and reducing the risk of human error. By boosting productivity and efficiency, your team can focus on more strategic tasks requiring expertise.

Cost-Effective Investment: Pre-Stretch System for Film Usage and Savings

The pre-stretch system incorporated into our pallet wrappers maximizes film usage. It minimizes waste, resulting in significant cost savings over time. Investing in our machines offers numerous benefits, including improved stability during transportation, labor, and time savings, and cost reduction.

Enhanced Product Protection: Reliable Barrier Against Moisture, Dust, and Tampering

Our pallet-wrapping machines are designed to provide unparalleled protection and security for your palletized goods. The tight and secure wrapping they produce is a formidable barrier against moisture, dust, and tampering, ensuring your products remain intact and presentable throughout their journey. Our pallet wrapping solutions ensure your products arrive at their destination undamaged and without interference. Additionally, We ensure to keep every product in good condition.

Versatility for All Industries: Perfect Solution for Your Specific Needs

The pallet wrappers are versatile and can adapt to different uses for various industries and purposes. Whether you run a warehouse, manufacturing plant, retail outlet, or online store, our range of machines ensures efficient palletization, secure packaging, and seamless logistics operations.

Revolutionize Your Packaging with the Pallet Wrapper

The Pallet Wrapper – Pallet Stretch Wrapping Machines revolutionize packaging with efficiency, cost savings, and enhanced product protection. Optimize your packaging operations, secure your goods, and elevate your business by investing in our machines. Discover the different models offered and start your journey towards a better and more dependable packaging solution today.

Upgrade Your Packaging Process: Experience the Benefits of Our Pallet Wrapper

Be sure to take advantage of our pallet wrapper’s advantageous features. Elevate your packaging process by upgrading to our high-quality product and witnessing the transformation. Our team provides customized solutions that meet your requirements. Contact us today to explore our range of services.